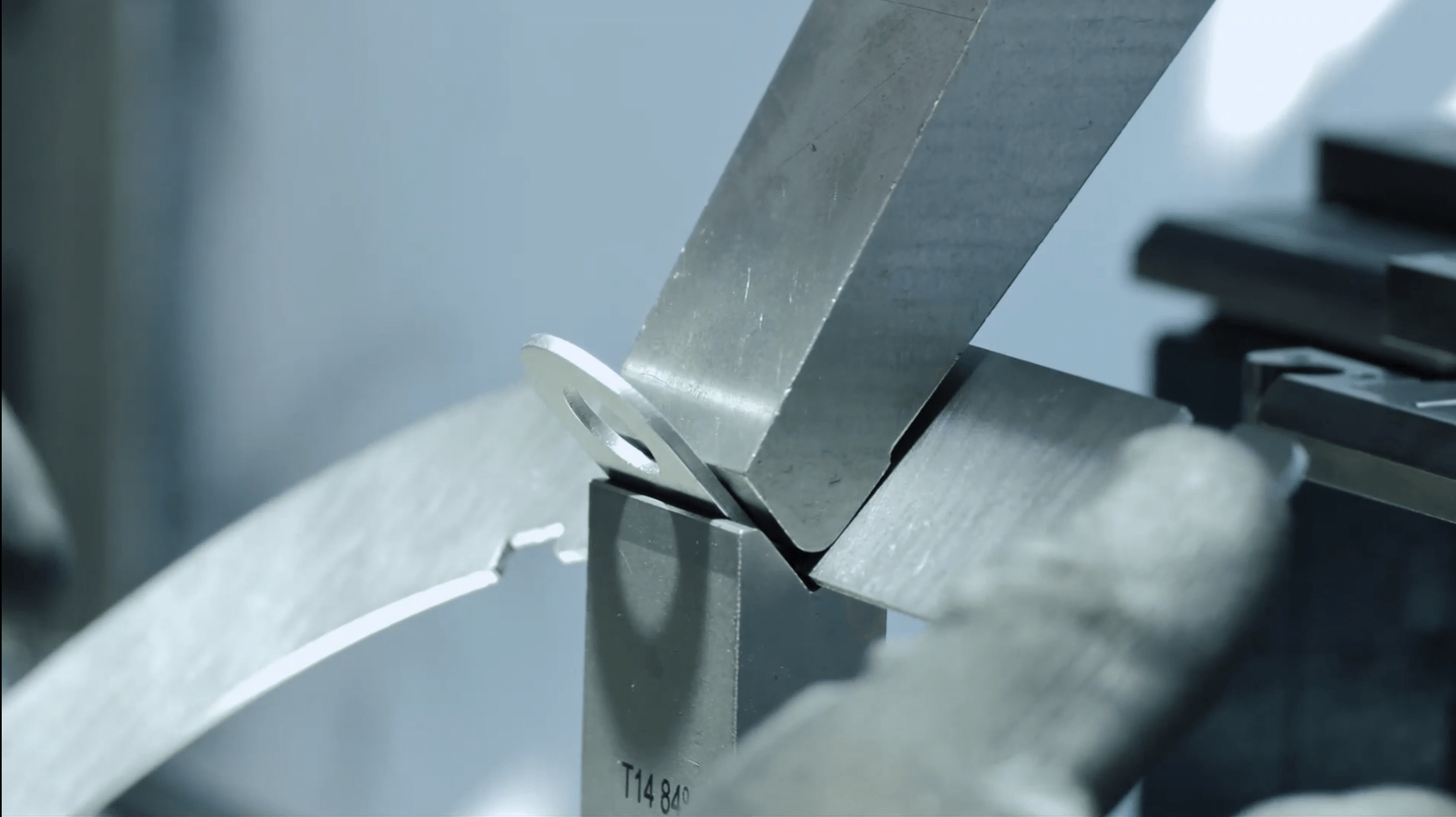

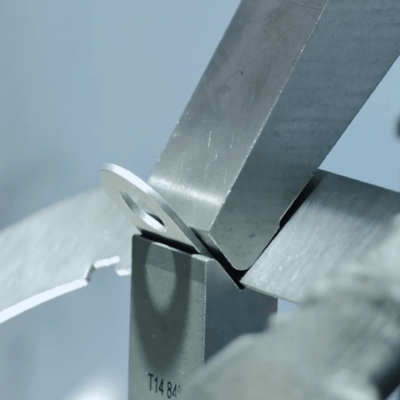

Precise bending with the use of press brakes which guarantees the repeatability of shapes and sizes

We provide sheet bending and rolling services in Poland. We guarantee 100% repeatability of shapes and sizes of produced elements

What technologies do we use?

For sheet bending, we use modern CNC press brakes from one of the leading manufacturers on the market – Trumpf.

- The maximum tonnage of our press is 230 t

- The maximum bending length is 3230 mm

- Thickness of the material up to 12mm

- We program any bending angle with a high accuracy of punch positioning (up to 0.005 mm).

Sheet rolling is possible thanks to a 4-roll, fully controlled CNC MG-MH 2010 rolling mill. The machine can roll elements with:

- The maximum length of 2m

- Thickness of 10 mm

- Minimum coiling radius of R150 mm.

In 4-roll machines the rolled sheet is clamped between the driven upper and bottom roll, bending is carried out by the moving side rolls. Such a construction minimises the length of the straight section and ensures high precision of coiling.

The CNC control used in our machine makes it possible to create complex shapes such as ovals and ellipses, and guarantees high accuracy and repeatable execution of elements